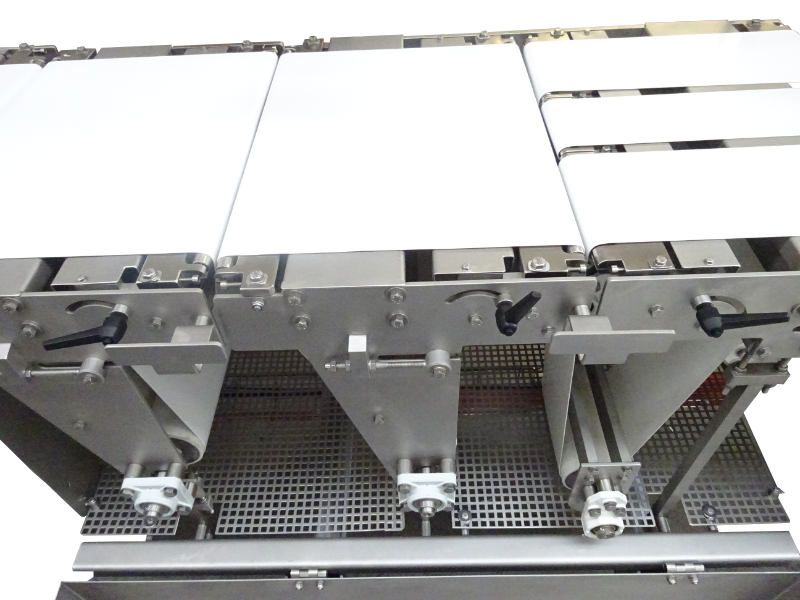

Whether they are narrow very high speed conveyor belts or very wide ones for handling products in rows, LM belt conveyors are all designed with the same efficiency criteria, modularity, simplicity of maintenance and cleaning. Depending on the applications, the position in the line and of the product, LM belt conveyors the following standard characteristics:

- Rotating knife edge ends of various diameters

- Automatic belt centring systems (electro-pneumatic or only pneumatic)

- Belt tensioning systems (centralised mechanical or pneumatic automatic)

- Tilting of the end knife edges to release belt tension for maintenance/cleaning

- Cantilever design for easy belt replacement

- Cooling system of the sliding surfaces and end knife edges

- Pneumatic or electric extraction/vacuum systems for perfect control of the product

- Line aligner with pneumatic or electric control

- Fixed, vibrating or motorised (V-blade) plate guide system for alignment, channelling or side diverting

- Fixed or vibrating channelling chutes

- Stacking systems

- Retracting knife edge, swinging knife edge or blowing air rejection systems

- Swinging knife edge vertical diverter systems with pneumatic or motorised control